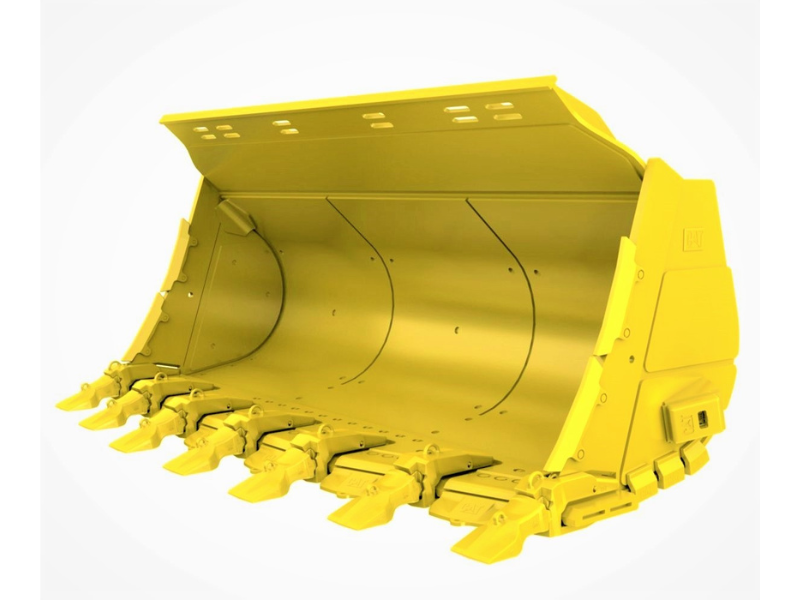

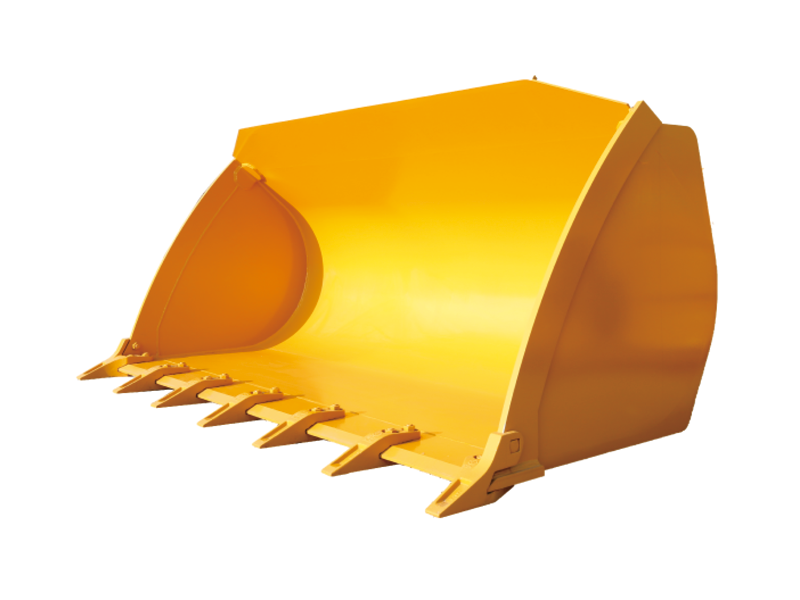

An Excavator Loader Bucket in chennai is a durable and versatile attachment used for digging, scooping, carrying, and dumping materials like soil, sand, gravel, and debris. Built with high-strength steel and reinforced at stress points, it withstands heavy loads and harsh environments. Available in different sizes and edge designs, these buckets suit tasks ranging from earthmoving to site clearing. Their compatibility with quick couplers adds efficiency, making them a reliable tool across construction, mining, and industrial projects.

An excavator loader bucket is a heavy-duty attachment used for digging, scooping, carrying, and dumping materials like soil, sand, gravel, or debris. It is one of the most versatile buckets, featuring a wide, deep design that allows larger material loads per cycle.

Built from reinforced, wear-resistant steel, loader buckets are designed for durability and efficiency. They often include cutting edges or teeth for better penetration in tough ground.

Key benefits include:

Large capacity for faster loading and fewer cycles.

Versatility to handle different materials and site tasks.

The Loader Bucket is built for volume and speed, while the Digging Bucket is designed for penetration and strength.

Design – Wide, open mouth with a flat edge for scooping and leveling, unlike digging buckets with teeth for breaking ground.

Capacity – Larger size moves more material per cycle, ideal for bulk handling.

Excavator loader buckets are built for strength, durability, and efficient material handling.

High-Strength Steel – Wear-resistant construction with reinforced cutting edges and side plates.

Optimized Shape – Curved profile for better penetration, quick filling, and smooth dumping.

Replaceable Teeth & Edges – Easy maintenance with options for general-purpose or heavy-duty use.

Reinforced Build – Gussets, liners, and wear strips extend bucket life under tough conditions..

The Excavator Loader Bucket is a versatile attachment designed for heavy-duty digging, loading, and material handling. Its strength and adaptability make it essential across industries such as:

Construction – Excavating, site leveling, backfilling, and loading aggregates or debris.

Mining & Quarrying – Digging and loading rocks, ores, coal, and minerals.

Agriculture & Forestry – Moving soil, manure, silage, crops, or logs.

Waste Management – Handling municipal waste, scrap, and demolition debris.

Excavator loader buckets are designed in multiple types to suit different materials and job conditions. Key variants include:

General-Purpose Buckets (GP): Standard use for soil, sand, gravel, and light aggregates.

Heavy-Duty Buckets (HD): Reinforced design for compact soil, clay, and mixed materials.

Rock Buckets: Built with extra strength for hard rock, quarry, and demolition work.

Ditching / Grading Buckets: Wide, toothless design for finishing, leveling, and backfilling.

Excavator loader buckets are designed in multiple types to suit different materials and job conditions. Key variants include:

General-Purpose Buckets (GP): Standard use for soil, sand, gravel, and light aggregates.

Heavy-Duty Buckets (HD): Reinforced design for compact soil, clay, and mixed materials.

Rock Buckets: Built with extra strength for hard rock, quarry, and demolition work.

Ditching / Grading Buckets: Wide, toothless design for finishing, leveling, and backfilling.

Excavator loader buckets are mainly designed for excavators, but they can be fitted on different types of machines depending on the job:

Crawler Excavators – Most common use; ideal for digging, loading trucks, and bulk handling on rough terrain.

Mini Excavators – For light-duty tasks like landscaping, trench backfilling, and small-scale loading.

Using a loader bucket with an excavator offers multiple advantages that boost productivity and efficiency on-site:

High Capacity – Move large volumes of soil, sand, gravel, or debris in fewer cycles.

Versatile – Suitable for earthmoving, backfilling, loading, and clearing.

Efficient – Faster cycle times mean quicker project completion.

Durable – Built with heavy-duty materials and wear-resistant edges for long life.

Choosing the right excavator loader bucket improves productivity, protects your machine, and saves costs. Here’s what to consider:

Application – Match the bucket to the job:

General construction: Standard bucket.

Heavy-duty/mining: Reinforced bucket for rocks.

Landscaping: Light, large-capacity bucket.

Material Type –

Light (soil, sand): Larger capacity.

Abrasive (rock, debris): Smaller, heavy-duty.

Sticky (clay): Smooth, wear-resistant design.

Proper upkeep of your excavator loader bucket ensures long service life, reduced downtime, and maximum efficiency.

Regular Checks: Inspect for cracks, wear, and material build-up daily.

Teeth & Cutting Edge: Monitor wear, replace on time, and rotate teeth for even use.

Pins & Bushings: Grease regularly, check for looseness, and replace when worn.

Excavator loader buckets are widely used across industries for digging, loading, and material handling. Some common applications include:

Construction & Infrastructure – Site clearing, foundation digging, backfilling, and transporting aggregates.

Mining & Quarrying – Loading ores, rocks, and managing stockpiles in tough conditions.

Agriculture & Farming – Moving soil, fertilizer, feed, and harvested crops.

1. What’s the difference between an excavator and a loader bucket?

Excavator buckets dig; loader buckets scoop and load. Excavator loader buckets combine both functions.

2. Are all buckets the same size?

No. Sizes vary by machine, material, and application.

3. Can one bucket handle all materials?

General-purpose buckets work for many tasks, but specialized buckets perform better for rock, demolition, or light materials.

4. How long does a bucket last?

With proper care and timely part replacement, buckets last several years even under heavy use.

5. Do loader buckets need maintenance?

Yes. Regular checks for cracks, wear, and loose bolts extend life and improve safety.

Excavator Rock Bucket | Excavator Skeleton Bucket | Excavator Trapezoidal Bucket | Excavator Soil Bucket | Excavator Loader Bucket | Excavator Single-Shank Ripper | Excavator Triple-Shank Ripper | Excavator Track Link Assembly | Excavator Tooth Points | Excavator JCB Teeth & Side Cutter | Excavator Idler | Excavator Sprocket | Excavator Lower Roller | Excavator Undercarriage | Excavator Track Group | Excavator Bolts | Excavator Rock Bucket in Chennai | Excavator Skeleton Bucket in Chennai | Excavator Trapezoidal Bucket in Chennai | Excavator Soil Bucket in Chennai | Excavator Loader Bucket in Chennai | Excavator Single-Shank Ripper in Chennai | Excavator Triple-Shank Ripper in Chennai | Excavator Track Link Assembly in Chennai | Excavator Tooth Points in Chennai | Excavator JCB Teeth & Side Cutter in Chennai | Excavator Idler in Chennai | Excavator Sprocket in Chennai | Excavator Lower Roller in Chennai | Excavator Undercarriage in Chennai | Excavator Track Group in Chennai | Excavator Bolts in Chennai | Excavator Rock Bucket in India | Excavator Skeleton Bucket in India | Excavator Trapezoidal Bucket in India | Excavator Soil Bucket in India | Excavator Loader Bucket in India | Excavator Single-Shank Ripper in India | Excavator Triple-Shank Ripper in India | Excavator Track Link Assembly in India | Excavator Tooth Points in India | Excavator JCB Teeth & Side Cutter in India | Excavator Idler in India | Excavator Sprocket in India | Excavator Lower Roller in India | Excavator Undercarriage in India | Excavator Track Group in India | Excavator Bolts in India

TEAM. All Rights Reserved. Developed by Pixel Tech.