When it comes to the performance and longevity of heavy equipment, the excavator undercarriage plays a critical role. As one of the most expensive components of an excavator—sometimes accounting for up to 50% of the machine’s maintenance costs—it’s essential to keep it in optimal condition. One of the most effective ways to do this is through condition monitoring.

In this blog, we’ll explore how condition monitoring can help you save money, reduce downtime, and extend the lifespan of your excavator undercarriage.

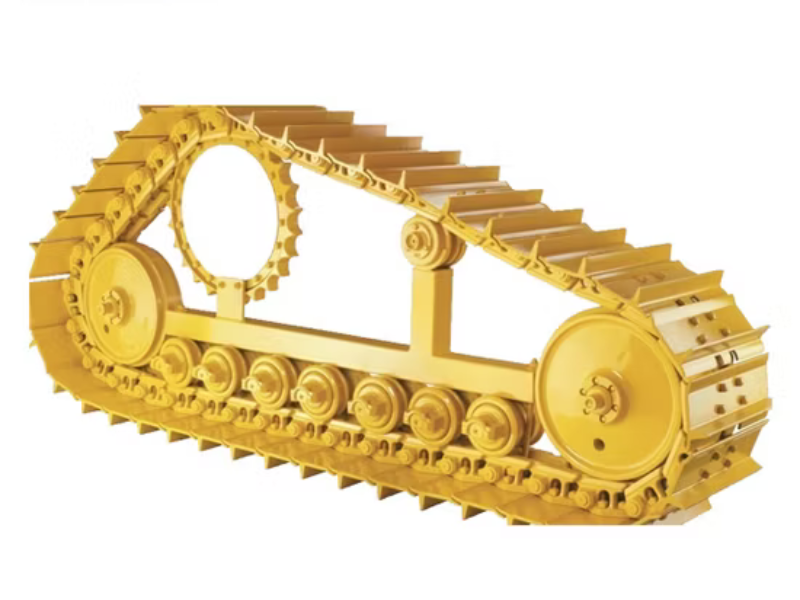

Condition monitoring refers to the process of continuously or regularly checking the state of a machine or its components using data-driven tools and inspections. For excavators, this includes monitoring temperature, vibration, pressure, wear, and alignment of the undercarriage components such as tracks, rollers, idlers, and sprockets.

The goal is simple: detect wear or failure before it happens, allowing for proactive maintenance rather than reactive repairs.

The excavator undercarriage is constantly subjected to tough environments—mud, rocks, uneven terrain, and heavy loads. Its components endure high levels of stress, especially in industries like construction, mining, and forestry.

Because of this, wear and tear is inevitable. Without regular monitoring, small issues can quickly escalate into major failures, resulting in expensive repairs, machine downtime, and project delays.

That’s where condition monitoring steps in.

Through routine inspections and advanced technologies (like ultrasonic testing, thermal imaging, or digital wear measurement tools), you can spot worn-out rollers, loose bolts, or misaligned tracks early on. This early detection allows you to schedule maintenance before a breakdown occurs.

Replacing a single worn-out track shoe or tightening a loose idler is far cheaper than replacing the entire undercarriage assembly. By using condition monitoring, you reduce the chance of catastrophic failures and the associated costs.

Downtime on an excavator is costly—not just in repair bills, but also in lost productivity. Scheduled maintenance based on condition monitoring allows you to fix problems before they stop your machine, helping projects stay on track.

Monitoring ensures components are kept within their optimal wear limits. Proper lubrication, tensioning, and cleaning can be done based on real-time data, significantly extending the lifespan of the undercarriage.

Here are key undercarriage components and what you should monitor:

Track Chains and Shoes: Look for elongation, wear, or cracks.

Rollers and Idlers: Monitor for proper alignment and signs of uneven wear.

Sprockets: Check for tooth wear and pitch errors.

Track Tension: Incorrect tension leads to accelerated wear; monitor it regularly.

Pins and Bushings: Wear here can lead to chain elongation and noise.

Advanced condition monitoring systems may also use IoT sensors to send real-time data to a centralized dashboard, enabling remote monitoring and predictive analytics.

Establish a Regular Inspection Schedule

Conduct daily visual inspections and more detailed checks weekly or monthly depending on usage.

Use Digital Monitoring Tools

GPS-based monitoring, telematics, and mobile apps can provide live data on usage, terrain stress, and wear patterns.

Document Everything

Maintain detailed records of wear patterns, repairs, and inspections to identify trends and plan ahead.

Train Operators and Maintenance Staff

Ensure your team knows how to spot issues, use monitoring tools, and perform preventive maintenance properly.

The excavator undercarriage is too valuable to leave unmonitored. With the right condition monitoring strategy, you can maximize uptime, minimize repair costs, and extend the operational life of your equipment. Whether you’re managing a single excavator or an entire fleet, proactive monitoring is an investment that pays for itself in the long run.

By integrating condition monitoring into your maintenance routine, you’re not just protecting your undercarriage—you’re safeguarding your entire project timeline and bottom line.

Excavator Rock Bucket | Excavator Skeleton Bucket | Excavator Trapezoidal Bucket | Excavator Soil Bucket | Excavator Loader Bucket | Excavator Single-Shank Ripper | Excavator Triple-Shank Ripper | Excavator Track Link Assembly | Excavator Tooth Points | Excavator JCB Teeth & Side Cutter | Excavator Idler | Excavator Sprocket | Excavator Lower Roller | Excavator Undercarriage | Excavator Track Group | Excavator Bolts | Excavator Rock Bucket in Chennai | Excavator Skeleton Bucket in Chennai | Excavator Trapezoidal Bucket in Chennai | Excavator Soil Bucket in Chennai | Excavator Loader Bucket in Chennai | Excavator Single-Shank Ripper in Chennai | Excavator Triple-Shank Ripper in Chennai | Excavator Track Link Assembly in Chennai | Excavator Tooth Points in Chennai | Excavator JCB Teeth & Side Cutter in Chennai | Excavator Idler in Chennai | Excavator Sprocket in Chennai | Excavator Lower Roller in Chennai | Excavator Undercarriage in Chennai | Excavator Track Group in Chennai | Excavator Bolts in Chennai | Excavator Rock Bucket in India | Excavator Skeleton Bucket in India | Excavator Trapezoidal Bucket in India | Excavator Soil Bucket in India | Excavator Loader Bucket in India | Excavator Single-Shank Ripper in India | Excavator Triple-Shank Ripper in India | Excavator Track Link Assembly in India | Excavator Tooth Points in India | Excavator JCB Teeth & Side Cutter in India | Excavator Idler in India | Excavator Sprocket in India | Excavator Lower Roller in India | Excavator Undercarriage in India | Excavator Track Group in India | Excavator Bolts in India

TEAM. All Rights Reserved. Developed by Pixel Tech.