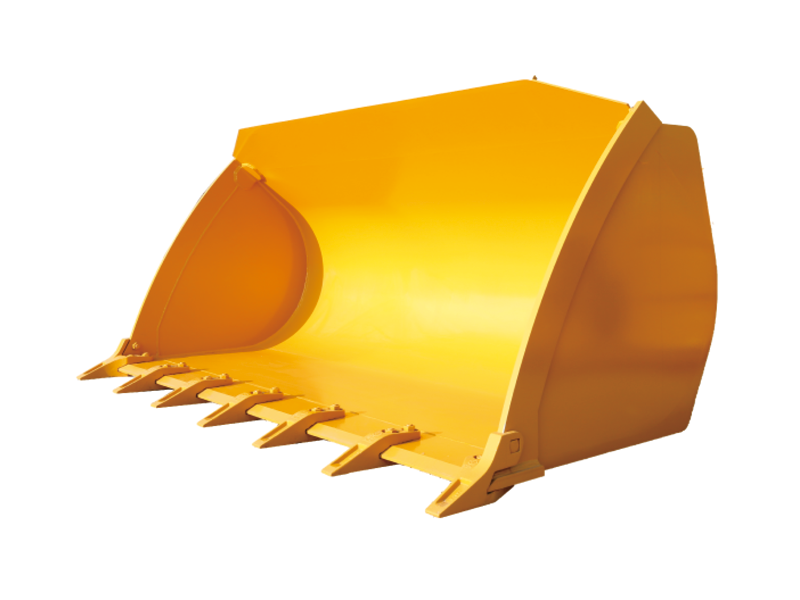

The Excavator Loader Bucket is one of the most vital components in earthmoving and construction machinery. It bears the brunt of digging, loading, and lifting operations daily, making its durability and design crucial for performance and longevity. While the shape, capacity, and edge design of the bucket are important, the materials used in manufacturing play an even greater role in determining how well it performs under extreme working conditions.

In this blog, we’ll explore the top materials used in manufacturing Excavator Loader Buckets, their properties, and why the right material selection truly matters for productivity, efficiency, and cost savings.

HSLA steel is one of the most common materials used in the fabrication of Excavator Loader Buckets. It combines strength, toughness, and weldability, which are essential for withstanding heavy loads and impacts.

Key Benefits:

Higher tensile strength compared to mild steel

Better resistance to wear and fatigue

Reduced weight for improved fuel efficiency

Excellent weldability and machinability

Why it matters:

HSLA steel ensures that the bucket can handle demanding excavation tasks without deformation or cracking. It also helps in maintaining the balance between strength and flexibility — two critical aspects for heavy-duty operations.

Another popular choice is abrasion-resistant (AR) steel, often used for bucket liners, cutting edges, and wear plates. Grades like AR400, AR450, and AR500 are specifically designed to resist abrasion from rocks, gravel, and sand.

Key Benefits:

Exceptional hardness (up to 500 Brinell)

High resistance to gouging and scraping

Prolonged bucket lifespan

Lower maintenance and replacement costs

Why it matters:

Excavator Loader Buckets face constant friction during digging and loading. AR steel minimizes wear on critical surfaces, reducing downtime and improving operational efficiency. This makes it an ideal choice for mining, quarrying, and demolition applications.

Boron steel is a type of steel alloy enhanced with boron — a small but powerful addition that significantly improves hardenability and strength. After proper heat treatment, boron steel achieves a high level of hardness and impact resistance.

Key Benefits:

Excellent toughness and ductility

High resistance to chipping and cracking

Enhanced surface hardness after heat treatment

Why it matters:

In environments where buckets constantly hit hard materials like rock or concrete, boron steel ensures longer service life and prevents premature wear, offering a balance between durability and cost-effectiveness.

Hardox®, a trademarked steel from SSAB, is a premium wear-resistant steel widely used in heavy equipment manufacturing. Hardox® steel provides superior strength and impact resistance, even at low thicknesses.

Key Benefits:

High hardness with outstanding toughness

Uniform mechanical properties across the plate

Lightweight yet extremely durable

Easy to fabricate and weld

Why it matters:

Hardox® ensures that Excavator Loader Buckets remain tough and reliable under continuous heavy use. It reduces bucket weight without compromising strength, leading to higher fuel efficiency and improved digging power.

Though not used for the entire structure, stainless steel and alloy steel are often used in certain bucket parts like pins, bushings, and bolts where corrosion resistance is crucial.

Key Benefits:

Resistance to rust and chemical corrosion

Increased lifespan in wet or acidic environments

Enhanced reliability of moving parts

Why it matters:

For buckets used in wet or coastal areas, corrosion can lead to early failures. Stainless and alloy steels protect key components, ensuring consistent performance and reducing maintenance intervals.

With advancements in material technology, some manufacturers are exploring composite reinforcements for bucket design. These include carbon-fiber reinforcements or polymer-based liners to reduce weight and increase wear resistance.

Key Benefits:

Lightweight structure with high strength

Reduced energy consumption

Lower noise and vibration during operation

Why it matters:

Although still in experimental stages for heavy machinery, composite materials could revolutionize bucket manufacturing by making them lighter, more efficient, and environmentally friendly.

Choosing the right material for an Excavator Loader Bucket directly impacts:

Performance: Determines how efficiently the bucket can dig, carry, and unload materials.

Durability: Reduces wear, cracks, and deformation, extending service life.

Operational Cost: Minimizes maintenance, downtime, and replacement frequency.

Safety: Prevents equipment failure during high-stress operations.

In short, the material defines how well the bucket can withstand the demands of its working environment — from mining and construction to agriculture and roadwork.

The Excavator Loader Bucket may appear as a simple attachment, but it’s a product of advanced engineering and material science. From HSLA and AR steels to boron and Hardox® plates, each material brings unique advantages that ensure superior performance, longevity, and reliability.

By understanding these materials, contractors and equipment owners can make informed decisions that enhance machine productivity and lower total ownership costs. After all, in the world of heavy machinery — the strength of the bucket defines the strength of the job.

TEAM. All Rights Reserved. Developed by Pixel Tech.