In construction, mining, and material handling operations, a loader bucket is one of the most crucial attachments for productivity. Whether attached to a wheel loader, skid steer, or backhoe, it plays a central role in moving soil, aggregates, ores, or other bulk materials efficiently. However, one of the biggest challenges operators face is material spillage—the loss of material during loading, carrying, or dumping. Spillage not only wastes valuable resources but also increases operational costs, clean-up time, and wear on equipment.

By adopting the right loader bucket loading techniques, operators can minimize spillage, improve efficiency, and extend the life of the bucket and machine.

Different materials have different flow characteristics. Fine sand behaves differently than wet clay or large gravel. Understanding the density, moisture content, and stickiness of the material allows operators to choose the correct loader bucket type and adjust loading techniques accordingly. For example:

Dry, free-flowing materials require careful bucket tilt control to prevent overflow.

Wet or sticky materials may require breakout force and shaking techniques to avoid material sticking to the bucket.

The angle at which the loader bucket enters the pile plays a big role in minimizing spillage. Approaching the material pile too steeply can cause the bucket to dig unevenly, leading to overfilling or losing material before lifting. A shallow, steady approach allows the bucket to fill evenly, reducing the chance of material spilling over the sides.

It might seem efficient to fill the loader bucket to its maximum capacity every time, but overfilling often leads to more spillage during transport. Instead, aim for a level load that matches the machine’s rated capacity. This prevents material from tumbling over the edges while moving and improves stability.

Once the loader bucket is filled, tilt it slightly back before lifting. This creates a “material pocket” inside the bucket, preventing spillage during travel. If the bucket is lifted without the proper tilt, the load is more likely to shift forward and spill. Additionally, lifting too quickly can cause loose material to shake out, so smooth, steady control is key.

Speed directly impacts how much material stays in the loader bucket. Moving too fast over uneven ground can cause the load to bounce and spill. Operators should adjust their speed based on terrain, bucket load, and material type to ensure a stable carry.

A well-planned route between the loading area and dumping point minimizes unnecessary movements and reduces the chances of spillage. Shorter travel distances, smoother turns, and fewer stops help keep the material inside the loader bucket.

Keeping the loader bucket closer to the ground during transport increases stability and reduces the risk of tipping or losing material. A lower center of gravity also helps prevent sudden spills if the loader passes over bumps or slopes.

Cracks, worn edges, or damaged side plates can lead to increased spillage. Regular inspection and maintenance of the loader bucket ensure that the attachment remains in optimal working condition. Replacing worn cutting edges and repairing cracks promptly will improve material retention.

Even the best loader bucket won’t prevent spillage if the operator uses poor techniques. Training programs should focus on correct approach, bucket control, and awareness of load limits. Experienced operators tend to handle material more efficiently, reducing waste and improving productivity.

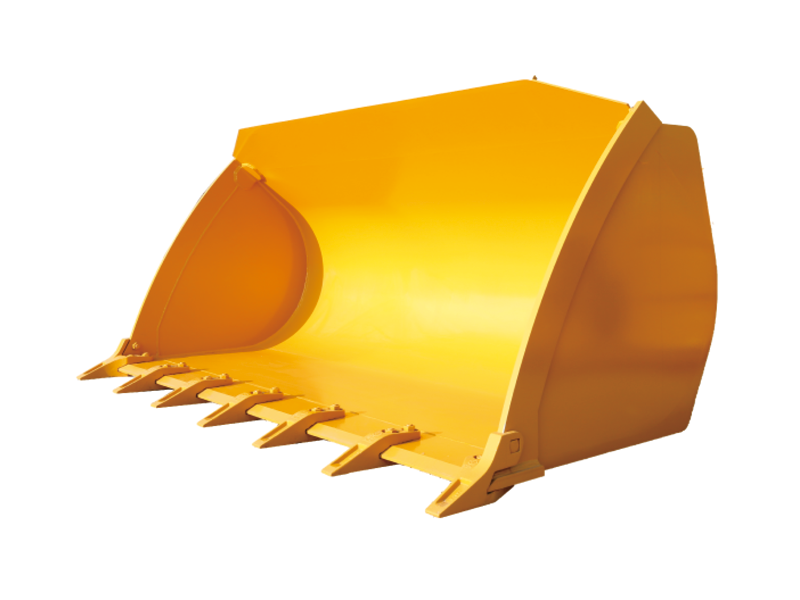

Some modern loader buckets come with spill guards, higher sides, or curved designs to hold more material securely. Choosing a bucket that matches the material type and job requirements can significantly reduce spillage without sacrificing productivity.

Minimizing spillage when using a loader bucket is about combining the right equipment with proper technique. By understanding material characteristics, maintaining the correct approach angle, avoiding overfilling, and using smooth travel and lift controls, operators can greatly improve efficiency. Regular bucket maintenance and operator training are equally important in reducing waste, cutting costs, and ensuring a safer, cleaner worksite.

The goal is not just to move material but to do it efficiently, safely, and with minimal loss. A well-used loader bucket is a powerful asset that can make the difference between an average job and an outstanding one.

TEAM. All Rights Reserved. Developed by Pixel Tech.