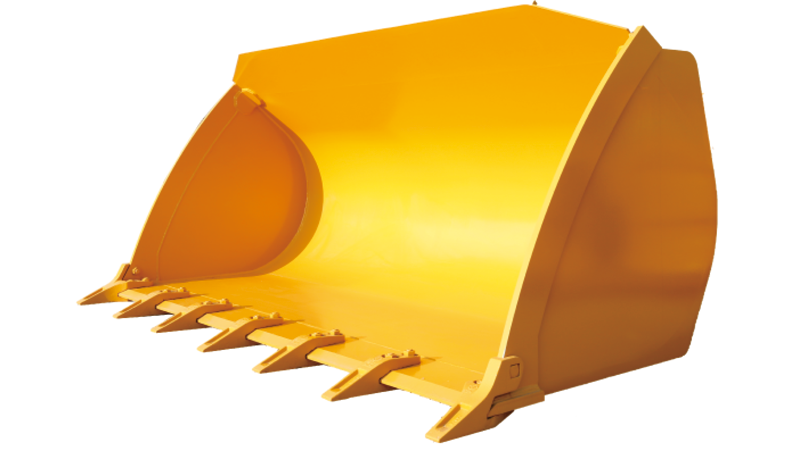

The loader bucket is one of the most versatile tools on a construction site. Whether you’re moving soil, gravel, sand, or debris, knowing how to properly fill a loader bucket is critical for both productivity and safety. Improper loading techniques not only reduce efficiency but also increase wear on your equipment and create serious safety risks.

In this article, we’ll walk you through the correct way to fill a loader bucket, highlighting best practices to ensure safe operation and prolong the life of your machine.

A loader bucket does more than just carry material—it affects the stability, maneuverability, and efficiency of the entire loader. Overloading, uneven loading, or using poor technique can:

By mastering the right techniques, operators can maximize the loader’s capabilities and minimize downtime.

Drive the loader straight towards the pile with the loader bucket slightly above the ground.

Keep the bucket level to avoid unnecessary contact with the ground that could damage cutting edges or wear plates.

Reduce speed as you get close to the pile to maintain control.

Tip: Approaching at a slight angle can sometimes help cut into dense material more effectively.

As you near the base of the pile, lower the loader bucket to a point where the cutting edge is slightly tilted forward (also called “racking forward”).

This allows the cutting edge to bite into the material rather than pushing it away.

Important: Avoid driving the loader bucket in with the arms too high or too low, as this can cause instability or excessive wear.

As the bucket enters the pile, gradually lift the loader arms while curling the bucket back.

This combined motion “scoops” material efficiently, reducing the chances of spillage.

Avoid jerky movements—smooth, steady control is key.

For sticky or heavy material, you may need to make a second pass to achieve a full load without overloading.

Once the loader bucket is full, curl it back completely to prevent spillage.

Keep the bucket low to the ground while transporting—this lowers the machine’s center of gravity and improves stability.

Do not overfill; carrying material heaped above the bucket edge increases the risk of losing the load and decreases visibility.

Mastering how to properly fill a loader bucket is more than a skill—it’s a vital safety practice. By using the right techniques, operators can work more efficiently, reduce machine wear, and ensure a safer environment on the job site.

Whether you’re a seasoned professional or new to operating loaders, following these steps will help you get the most out of your loader bucket while keeping operations safe and productive.

Excavator Rock Bucket | Excavator Skeleton Bucket | Excavator Trapezoidal Bucket | Excavator Soil Bucket | Excavator Loader Bucket | Excavator Single-Shank Ripper | Excavator Triple-Shank Ripper | Excavator Track Link Assembly | Excavator Tooth Points | Excavator JCB Teeth & Side Cutter | Excavator Idler | Excavator Sprocket | Excavator Lower Roller | Excavator Undercarriage | Excavator Track Group | Excavator Bolts | Excavator Rock Bucket in Chennai | Excavator Skeleton Bucket in Chennai | Excavator Trapezoidal Bucket in Chennai | Excavator Soil Bucket in Chennai | Excavator Loader Bucket in Chennai | Excavator Single-Shank Ripper in Chennai | Excavator Triple-Shank Ripper in Chennai | Excavator Track Link Assembly in Chennai | Excavator Tooth Points in Chennai | Excavator JCB Teeth & Side Cutter in Chennai | Excavator Idler in Chennai | Excavator Sprocket in Chennai | Excavator Lower Roller in Chennai | Excavator Undercarriage in Chennai | Excavator Track Group in Chennai | Excavator Bolts in Chennai | Excavator Rock Bucket in India | Excavator Skeleton Bucket in India | Excavator Trapezoidal Bucket in India | Excavator Soil Bucket in India | Excavator Loader Bucket in India | Excavator Single-Shank Ripper in India | Excavator Triple-Shank Ripper in India | Excavator Track Link Assembly in India | Excavator Tooth Points in India | Excavator JCB Teeth & Side Cutter in India | Excavator Idler in India | Excavator Sprocket in India | Excavator Lower Roller in India | Excavator Undercarriage in India | Excavator Track Group in India | Excavator Bolts in India

TEAM. All Rights Reserved. Developed by Pixel Tech.