When managing a fleet of excavators, one of the most critical decisions is choosing between heavy-duty and standard undercarriage systems. The excavator undercarriage plays a central role in machine performance, durability, and cost-efficiency, especially when working in demanding environments. Whether you’re operating in rocky terrains, soft soil, or urban construction sites, understanding the difference between these two types of undercarriages is essential to ensure maximum productivity and minimum downtime.

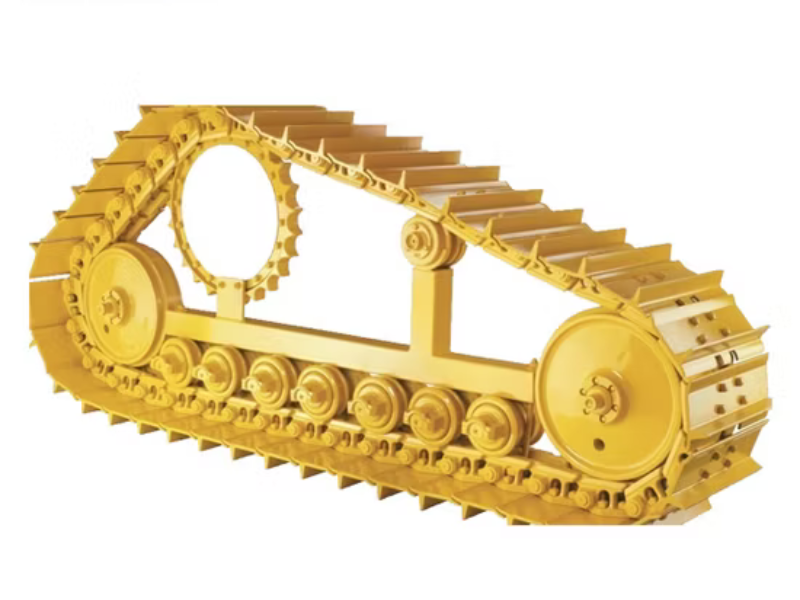

The excavator undercarriage includes all components that support the machine’s weight and enable movement—such as the tracks, rollers, idlers, sprockets, and track frames. These parts bear the brunt of the machine’s stress and wear, particularly in tough working conditions. Selecting the right undercarriage type can dramatically impact the excavator’s lifespan and operating costs.

A standard undercarriage is designed for general construction tasks and moderate conditions. It is typically lighter, more affordable, and easier to replace. These systems work best in applications where the ground is relatively soft, such as:

Residential construction

Landscaping

Agricultural projects

Light commercial work

Lower initial cost: Ideal for contractors on a tight budget or those with short-term projects.

Reduced machine weight: Lighter undercarriages reduce ground pressure, making them suitable for softer soil.

Easier to transport: Less weight translates into easier and cheaper transport between job sites.

Lower maintenance costs: Standard undercarriages are often easier and quicker to service, with cheaper replacement parts.

However, standard systems are not built for extreme stress. Using them in harsh conditions may lead to premature wear, higher maintenance frequency, and increased downtime.

A heavy-duty undercarriage is engineered to withstand extreme applications such as mining, demolition, forestry, and large-scale infrastructure work. These systems are more robust, using thicker and stronger components to resist wear and impact.

Reinforced components: Thicker steel, heat-treated parts, and high-strength bushings.

Enhanced durability: Designed for high-impact environments, reducing the risk of structural failures.

Increased load-bearing capacity: Suitable for larger, more powerful excavators that operate with heavy attachments.

Longer lifespan: Excellent return on investment for long-term, high-stress usage.

Less downtime: Withstand tough conditions with fewer breakdowns.

Higher resale value: Machines equipped with heavy-duty undercarriages often retain better resale value.

However, they do come with trade-offs:

Higher upfront cost: Heavier components and premium materials increase the initial investment.

Greater ground pressure: Heavier undercarriages can damage delicate surfaces, limiting where the excavator can be used.

More complex maintenance: Larger, more intricate parts can require longer repair times and specialized labor.

When comparing heavy-duty vs. standard undercarriage systems across your fleet, the decision should be driven by:

Project Demands: Are your machines mostly used in heavy civil construction, or do they handle light site work?

Terrain Type: Harsh, rocky, and abrasive terrain demands a heavy-duty undercarriage, while loamy or sandy soil may not.

Operating Hours: High-hour machines benefit from the longevity of a heavy-duty system.

Lifecycle Cost: Consider total cost of ownership—not just the purchase price but also fuel, maintenance, and downtime over time.

Many contractors opt for a mixed fleet—equipping some machines with standard undercarriages and others with heavy-duty systems. This allows them to assign the right machine to the right job, optimizing both cost and performance. A thoughtful mix also ensures better utilization of equipment and improves return on investment across the fleet.

Choosing the right excavator undercarriage type—whether heavy-duty or standard—is not just a mechanical decision; it’s a strategic one. While standard undercarriages offer cost-effective solutions for general work, heavy-duty systems shine in demanding environments where performance and durability are paramount. By assessing your operational needs, terrain challenges, and long-term goals, you can make an informed decision that enhances fleet efficiency and reduces ownership costs.

Excavator Rock Bucket | Excavator Skeleton Bucket | Excavator Trapezoidal Bucket | Excavator Soil Bucket | Excavator Loader Bucket | Excavator Single-Shank Ripper | Excavator Triple-Shank Ripper | Excavator Track Link Assembly | Excavator Tooth Points | Excavator JCB Teeth & Side Cutter | Excavator Idler | Excavator Sprocket | Excavator Lower Roller | Excavator Undercarriage | Excavator Track Group | Excavator Bolts | Excavator Rock Bucket in Chennai | Excavator Skeleton Bucket in Chennai | Excavator Trapezoidal Bucket in Chennai | Excavator Soil Bucket in Chennai | Excavator Loader Bucket in Chennai | Excavator Single-Shank Ripper in Chennai | Excavator Triple-Shank Ripper in Chennai | Excavator Track Link Assembly in Chennai | Excavator Tooth Points in Chennai | Excavator JCB Teeth & Side Cutter in Chennai | Excavator Idler in Chennai | Excavator Sprocket in Chennai | Excavator Lower Roller in Chennai | Excavator Undercarriage in Chennai | Excavator Track Group in Chennai | Excavator Bolts in Chennai | Excavator Rock Bucket in India | Excavator Skeleton Bucket in India | Excavator Trapezoidal Bucket in India | Excavator Soil Bucket in India | Excavator Loader Bucket in India | Excavator Single-Shank Ripper in India | Excavator Triple-Shank Ripper in India | Excavator Track Link Assembly in India | Excavator Tooth Points in India | Excavator JCB Teeth & Side Cutter in India | Excavator Idler in India | Excavator Sprocket in India | Excavator Lower Roller in India | Excavator Undercarriage in India | Excavator Track Group in India | Excavator Bolts in India

TEAM. All Rights Reserved. Developed by Pixel Tech.