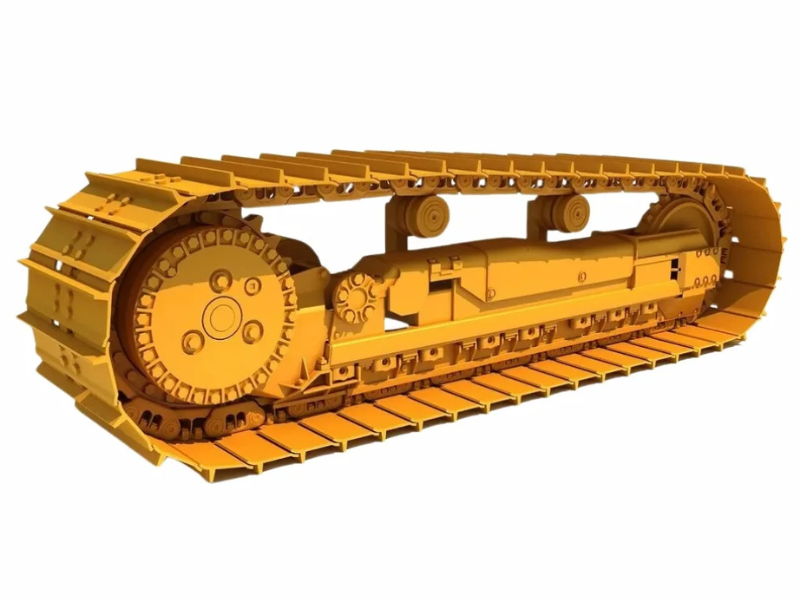

When it comes to heavy machinery, the excavator undercarriage is one of the most crucial yet often overlooked components. It supports the machine’s weight, ensures stability, and enables smooth operation across rugged terrains. However, the undercarriage is also one of the most expensive parts to repair or replace—often accounting for nearly 50% of the total maintenance costs of an excavator.

This makes regular inspection and maintenance not just a good practice but a necessity for extending undercarriage life, minimizing downtime, and maximizing return on investment.

The excavator undercarriage operates under extreme conditions—mud, rocks, abrasive materials, and uneven ground. Each of these factors contributes to accelerated wear and tear if left unchecked. Some of the common problems include:

Track wear due to improper tension or ground conditions.

Roller and idler damage from poor lubrication or debris buildup.

Loose bolts that compromise structural integrity.

Uneven wear patterns from incorrect operation or alignment issues.

Ignoring these signs can lead to sudden breakdowns, costly repairs, and lost productivity on the job site.

A proactive inspection routine for the excavator undercarriage provides multiple advantages, such as:

Longer Lifespan of Components

Early detection of wear allows for timely adjustments and replacement of minor parts before they cause larger failures.

Reduced Downtime

Planned maintenance reduces the likelihood of unexpected breakdowns that can halt projects.

Cost Savings

Addressing issues early is significantly cheaper than replacing an entire undercarriage assembly.

Improved Safety

A well-maintained undercarriage minimizes the risk of accidents caused by machine instability or track failures.

To keep your excavator undercarriage in optimal condition, it’s important to follow a structured inspection checklist.

Improper track tension is one of the leading causes of premature undercarriage wear. Tracks that are too tight strain the system, while loose tracks risk de-tracking. Operators should follow the manufacturer’s guidelines to adjust tension based on soil conditions.

Inspect rollers and idlers for uneven wear, cracks, or leaks. These components keep the track aligned and absorb significant stress, making them prone to damage. Proper lubrication is also vital.

Check sprocket teeth for wear. Sharp or broken teeth can reduce efficiency and cause accelerated track link damage.

Examine track shoes for bent plates, missing bolts, or excessive wear. Damaged shoes can destabilize the machine and increase strain on other undercarriage parts.

Loose or missing bolts compromise the integrity of the undercarriage. Routine tightening ensures structural stability.

In addition to inspections, operators can adopt the following habits to maximize excavator undercarriage longevity:

Operate on Level Ground When Possible: Reduces stress on tracks and alignment.

Avoid Excessive Speed and Sharp Turns: These actions accelerate wear and increase risk of de-tracking.

Keep the Undercarriage Clean: Regular cleaning removes mud, rocks, and debris that can cause abrasion and clog rollers.

Rotate or Replace Worn Components: Addressing small issues prevents uneven wear across the system.

Train Operators Properly: Skilled operation significantly reduces unnecessary strain on the machine.

Consistency is key when maintaining the excavator undercarriage. Operators should:

Perform daily visual checks before and after operation.

Conduct weekly detailed inspections focusing on track tension, rollers, and sprockets.

Schedule monthly maintenance checks by trained technicians.

Keeping records of these inspections helps track wear patterns and plan proactive replacements.

The excavator undercarriage is the backbone of machine performance, and its care should never be an afterthought. Through regular inspection, proper cleaning, and operator awareness, contractors can significantly extend the life of their undercarriage while reducing costs and downtime.

Investing in a proactive maintenance routine doesn’t just protect your equipment—it also safeguards your project timelines and profitability. In the long run, regular undercarriage inspection is not an expense but a smart strategy for efficiency and durability.

TEAM. All Rights Reserved. Developed by Pixel Tech.