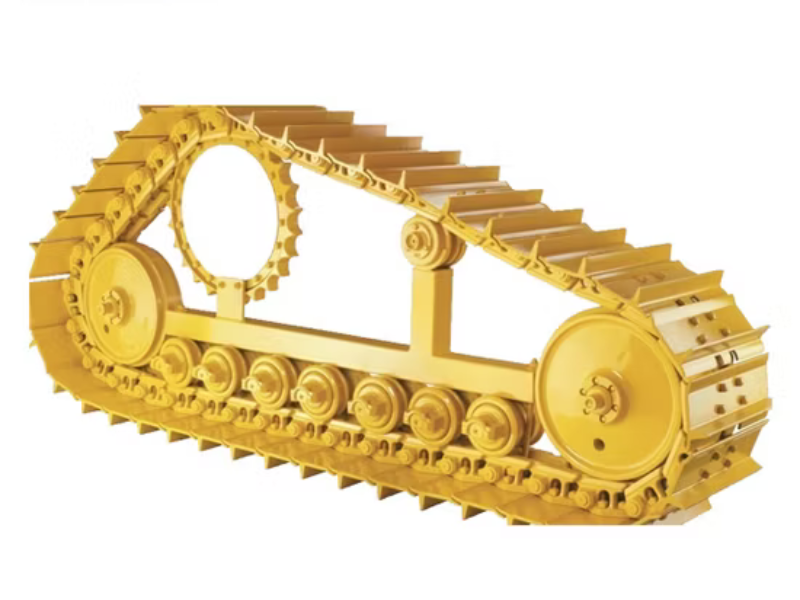

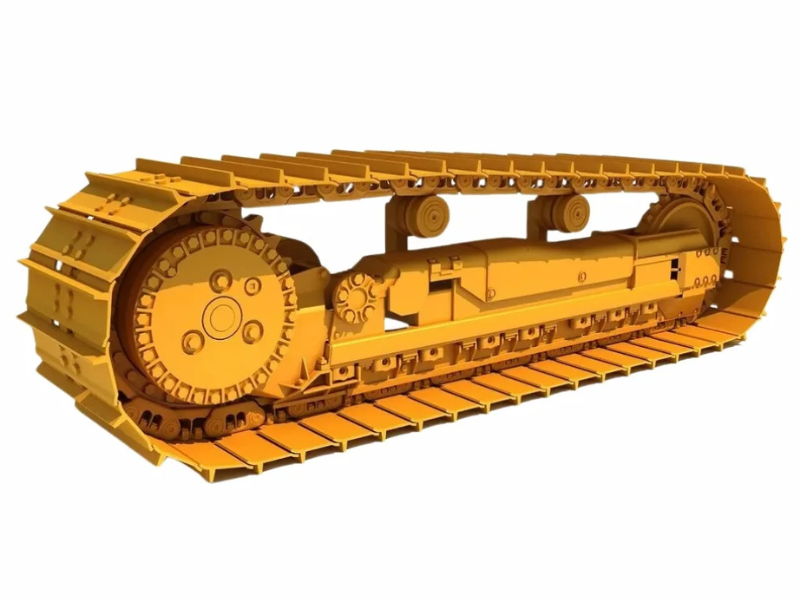

The Excavator undercarriage forms the foundation of an excavator, supporting its weight and enabling movement across tough terrains. It includes key components such as track chains, shoes, rollers, idlers, and sprockets, which work together to provide stability, traction, and smooth operation.

Because it constantly bears heavy loads and endures abrasive ground contact, the undercarriage is one of the most wear-prone areas of the machine. Proper inspection and maintenance are vital to minimize downtime, control repair costs, and ensure long-term performance.

The undercarriage supports the excavator’s weight, transfers power to the ground, and ensures stability on different terrains. Its main parts include:

Track Chains (Crawler Tracks): Continuous steel or rubber links that distribute weight and provide traction.

Track Shoes (Grousers): Bolted plates that grip the ground; single-grouser for rough terrain, triple-grouser for balanced use.

The undercarriage is the backbone of an excavator, and its durability directly affects performance and cost-efficiency. A strong undercarriage ensures:

Stability & Balance – Better weight distribution for safe digging, lifting, and maneuvering on tough terrain.

Traction & Mobility – Reliable grip on soil, mud, or slopes for smooth, efficient movement.

Excavator undercarriages face constant stress from rocks, mud, water, and heavy loads. To perform in such harsh conditions, they are built with specialized materials and rugged construction.

High-Strength Steel: Track shoes, links, and sprockets use alloy steels (like manganese or chromium-molybdenum) with heat treatment for toughness and wear resistance.

Wear Protection: Pins, bushings, and rollers are hardened to resist abrasion and extend service life.

Sealed & Lubricated Designs (SALT): Prevent dirt and water entry, ensuring smooth operation with minimal maintenance.

Modern excavators use advanced undercarriage systems to improve durability, performance, and reduce ownership costs.

Heavy-Duty Tracks – Reinforced shoes and frames handle rock, demolition, and mining.

SALT Chains – Sealed & lubricated designs reduce friction and extend track life.

Rotating/Extended-Life Bushings – Even wear patterns for longer service intervals.

The undercarriage is the backbone of an excavator and one of its highest maintenance costs. Proper care directly impacts machine life, uptime, and operating costs.

Key Practices:

Daily Cleaning & Inspection: Remove mud and rocks, check for leaks, cracks, or unusual wear.

Correct Track Tension: Avoid both slackness (derailments) and over-tightening (stress on rollers and idlers).

Lubrication: Keep pins, bushings, rollers, and idlers properly greased with the right lubricant.

The undercarriage is the backbone of an excavator, directly affecting stability, performance, and operating costs. Choosing the right system depends on your jobsite, machine type, and budget. Here’s what to consider:

Work Environment:

Rocky terrain → Heavy-duty steel tracks, reinforced rollers.

Soft/muddy ground → Wider or low-ground-pressure tracks.

Urban sites → Rubber tracks or pads to protect surfaces.

Your excavator’s undercarriage takes heavy wear every day, and spotting issues early prevents costly downtime. Watch for these warning signs:

Uneven or Excessive Track Wear – indicates misalignment or poor tension.

Frequent De-Tracking – caused by loose tension, worn idlers, or damaged shoes.

Cracked or Bent Track Shoes – reduce grip and stability.

Worn Rollers & Idlers – look for flat spots, leaks, or abnormal noise.

A strong undercarriage is the backbone of excavator performance, directly influencing efficiency, safety, and operating costs.

Stability & Control: Provides balance on rough terrain and during heavy lifting.

Longer Lifespan: Reduces stress on machine components, delaying wear and tear.

Operators value the triple-shank ripper for its ability to cut through hard soil, frozen ground, and rock more efficiently than single-shank designs. By spreading force across three teeth, it boosts productivity, lowers wear, and reduces fuel use during excavation. Many note its reliability in land clearing, mining, and roadwork, as well as the ease of maintaining replaceable shanks. In the field, it proves to be a versatile tool that saves time, extends machine capability, and delivers consistent performance in tough conditions.

Q1: What is an excavator undercarriage?

It’s the lower framework that includes tracks, rollers, idlers, and sprockets. It supports the machine’s weight and enables movement.

Q2: Why is it important?

The undercarriage accounts for nearly half of ownership costs. Proper care improves performance, fuel efficiency, and reduces downtime.

Q3: How often should I inspect it?

Check daily for wear, loose bolts, abnormal tension, or cracks to prevent costly breakdowns.

Q4: What are common signs of wear?

Uneven track wear, loose links, abnormal noises, cracked rollers, or frequent de-tracking.

Q5: How long does it last?

With good maintenance, 4,000–6,000 hours, but harsh terrain shortens lifespan.

Q6: What causes early wear?

Improper track tension, rocky ground, high-speed travel, steep slopes, and poor cleaning.

Q7: How can I extend its life?

Maintain track tension, clean debris after shifts, operate moderately, and lubricate regularly.

Q8: What’s the right track tension?

Tracks should sag slightly (about 1–2 inches). Too tight = faster wear; too loose = de-tracking.

Q9: Can I replace single parts?

Yes, but if wear is widespread, replacing the full set prevents uneven wear.

Q10: Steel vs rubber tracks?

Steel = heavy-duty and durable. Rubber = quieter, less surface damage, good for urban work.

TEAM. All Rights Reserved. Developed by Pixel Tech.