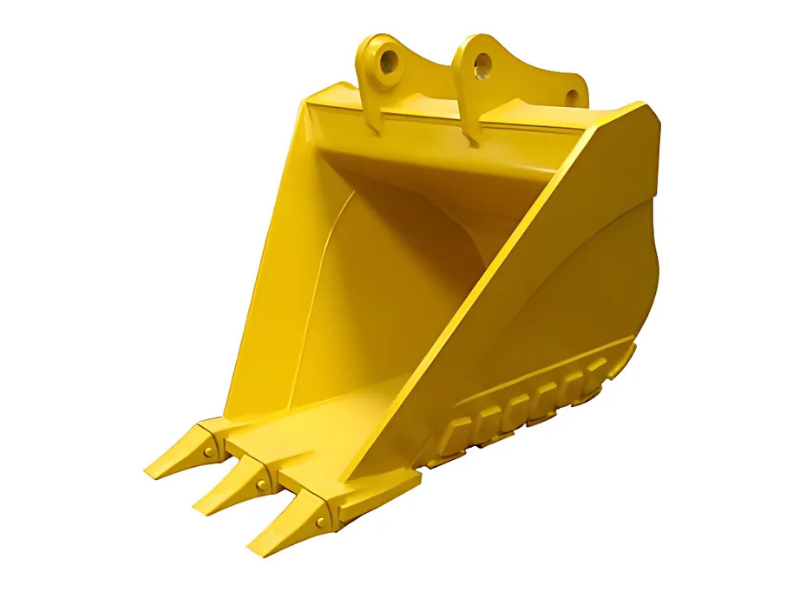

An Excavator Trapezoidal Bucket is a specialized attachment designed for precision trenching, canal shaping, and ditch maintenance. Its trapezoidal profile—wider at the top and narrower at the bottom—allows for accurate V-shaped cuts, reducing excess soil removal and improving efficiency.

Made from high-strength, wear-resistant steel, it offers durability and long service life, even in abrasive conditions. Widely used in civil engineering, agriculture, and drainage projects, the trapezoidal bucket delivers consistent trench profiles, saves time, and lowers operational costs.

An Excavator Trapezoidal Bucket (also called a V-bucket) is a specialized attachment designed for digging precise trenches with sloped sides. Its trapezoid-shaped profile, with angled side walls and a flat or slightly curved bottom, allows for accurate ditching in fewer passes.

These buckets are widely used for irrigation canals, drainage ditches, utility trenching, and landscaping, where clean and uniform trench shapes are essential. Built from heavy-duty steel with reinforced edges, they ensure durability and efficient performance across different soil conditions.

In short, a trapezoidal bucket is the go-to tool for efficient, accurate, and cost-effective trenching and ditching.

The Excavator Trapezoidal Bucket is designed to deliver precise cuts, stable slopes, and efficient excavation, making it highly effective in trenching, ditching, and pipeline works.

Trenches: Creates uniform profiles for utilities like cables, water lines, and drains with reduced backfill and faster digging.

Ditches: Perfect for irrigation and drainage channels, ensuring consistent slopes and smooth water flow with minimal finishing work.

Pipelines: Forms accurate trench beds for oil, gas, or water pipelines, providing stable walls and safer installation conditions.

Excavator trapezoidal buckets are mainly available in two functional variants — Creation Buckets and Reprofiling Buckets.

Use: Forming new trenches, canals, or ditches.

Features: Sharp cutting edges, accurate side angles (30°, 45°, 60°).

Applications: Irrigation canals, drainage lines, utility pipeline trenches.

Advantage: Produces clean, uniform profiles from raw ground.

Use: Maintenance and reshaping of existing trenches/canals.

Features: Wear-resistant edges, reinforced design for repeated grading.

Applications: Clearing silt, restoring canal profiles, ditch upkeep.

Advantage: Extends trench life and ensures proper flow without full re-excavation.

Trapezoidal Shape – Creates V-shaped trenches with accurate angled sidewalls.

Optimized Side Angles – Commonly 30°, 45°, or 60° for precise trench profiles.

Reinforced Cutting Edges – Strong bottom and side blades for better penetration and wear resistance.

High Capacity – Flared sidewalls allow faster digging and material handling.

Durable Build – Heavy-duty steel and optional side cutters for extended life.

Smooth Finishing – Delivers neat trenches without extra shaping.

Versatile Use – Ideal for canals, drainage, pipelines, irrigation, and landscaping.

Customizable – Available in different widths, depths, and side angles.

Precision Shaping – Creates sloped trench walls directly, reducing the need for rework or reshaping.

Material Efficiency – Cuts only the required profile, avoiding excess excavation and backfilling.

Better for Drainage/Irrigation – Trapezoidal profile ensures smooth water flow and minimizes erosion.

Time & Fuel Savings – Fewer passes needed, lowering machine hours, fuel use, and wear.

Cleaner Finish – Delivers accurate slopes and neat profiles with minimal manual finishing.

Task-Specific Performance – Ideal for canals, ditches, landscaping, and roadwork shoulders where precision is key.

The trapezoidal bucket is engineered to fit a wide range of excavators, from 2-ton mini machines to 40+ ton heavy excavators.

Mini Excavators (2–8 tons): Precise trenching and landscaping.

Medium Excavators (8–20 tons): Roadworks, irrigation, and utility trenching.

Large Excavators (20–40+ tons): Heavy-duty canal and infrastructure projects.

Buckets are available in pin-on or quick coupler designs, compatible with major OEMs like Caterpillar, Komatsu, Volvo, JCB, Hitachi, Hyundai, and more. Custom pin sizes, widths, and sidewall angles (45°, 60°, etc.) can be tailored to project needs.

Optimized for the host machine’s hydraulic system and breakout force, the bucket ensures reliable performance in drainage, ditching, and canal works across different machine classes.

Trapezoidal buckets can be tailored with add-ons to boost efficiency, durability, and versatility:

Cutting Edges – Bolt-on, weld-on, or segmented for better wear resistance and easy replacement.

Side Protection – Bolt-on side cutters, heel shrouds, and wear plates to extend bucket life.

Teeth Choices – Standard, heavy-duty, twin tiger, or chisel teeth to match soil conditions.

Utility Add-ons – Drainage holes to reduce soil carry-back, lifting hooks for handling pipes or materials.

Custom Profile & Widths – Adjustable bucket widths and side slope angles (30°, 45°, or custom).

Mounting Options – Pin-on, quick coupler, or tiltrotator-compatible designs for faster attachment changes.

Material & Finish – HARDOX/AR steel, protective coatings, or lightweight builds for specific job needs.

Choosing the right trapezoidal bucket ensures accurate trenching, higher efficiency, and longer machine life. Key factors to consider:

Excavator Size – Match the bucket to your machine’s weight class and hydraulic capacity.

Trench Dimensions – Select the right width and sidewall angle (30°, 45°, or 60°) based on project needs.

Soil Conditions – Use standard buckets for soft soils; reinforced heavy-duty buckets for rocky or abrasive ground.

Sidewall Angle – 45° is common for irrigation and drainage; adjust angles for specialized applications.

Build Quality – Choose high-strength steel with wear strips, cutting edges, and reinforced corners.

Compatibility – Ensure it fits your excavator’s coupler or pin-on system for smooth operations.

Efficiency – A properly sized bucket reduces passes, fuel consumption, and overall costs.

To keep your trapezoidal bucket reliable and long-lasting, follow these key practices:

Inspect Regularly – Check for cracks, edge wear, and weld fatigue before and after use.

Maintain Cutting Edges & Teeth – Sharpen or replace worn parts to reduce stress on the excavator and ensure efficient digging.

Control Wear & Abrasion – Use wear plates or hardfacing in abrasive soils; clean the bucket after each job to prevent rust.

Lubricate Pins & Bushings – Keep joints greased and replace worn pins to prevent misalignment.

Prevent Corrosion – Apply protective coatings and store in a dry, covered place when idle.

Use Properly – Avoid misuse as a breaker or lifter; operate at correct digging angles and within machine capacity.

Service on Schedule – Follow OEM maintenance intervals and keep a logbook for checks and repairs.

Train Operators – Ensure operators use correct digging techniques and adjust force for soil conditions.

Excavator trapezoidal buckets are specialized for precise ditching, trenching, and shaping tasks. Their V-shaped design ensures accuracy, efficiency, and reduced rework across multiple industries:

Canal & Irrigation Works – Perfect for digging canals, drainage ditches, and irrigation channels with uniform slopes.

Roadside Drainage – Speeds up stormwater and culvert excavation while maintaining design accuracy.

Agriculture – Shapes field channels and drains for better irrigation and water management.

Utility & Pipeline Projects – Creates stable, sloped trenches for laying pipes, cables, and sewage systems.

Flood Control & Environmental Projects – Useful for flood channels, levees, and wetland restoration.

Mining & Quarrying – Builds drainage ditches to divert water and improve site safety.

Municipal Infrastructure – Ensures efficient excavation of urban drains and sewage channels.

1. What is a trapezoidal bucket?

A specialized excavator bucket with sloping sides, designed for digging and shaping ditches, canals, and trenches.

2. What is it used for?

Ideal for irrigation canals, drainage ditches, pipeline trenches, landscaping, and road drainage.

3. How is it different from a standard bucket?

It creates trapezoidal or V-shaped profiles in one pass, saving time and fuel.

4. What sizes are available?

Widths usually range from 400 mm to 1800 mm with side angles of 30°–60°. Custom options are available.

5. Can it fit any excavator?

Yes, as long as the bucket matches the machine’s weight, hydraulic capacity, and coupler system.

6. What materials is it made of?

High-strength, wear-resistant steel with reinforced cutting edges for durability.

7. Does it work in all soil types?

Yes, except for very rocky or compacted soils where a rock bucket or ripper is better.

8. Can it be customized?

Yes—width, angles, cutting edges, and reinforcement can be tailored to project needs.

9. How do I maintain it?

Check for wear, grease pivot points, replace edges/teeth when needed, and store properly.

10. Who uses trapezoidal buckets?

Construction, agriculture, landscaping, and civil engineering industries.

Excavator Rock Bucket | Excavator Skeleton Bucket | Excavator Trapezoidal Bucket | Excavator Soil Bucket | Excavator Loader Bucket | Excavator Single-Shank Ripper | Excavator Triple-Shank Ripper | Excavator Track Link Assembly | Excavator Tooth Points | Excavator JCB Teeth & Side Cutter | Excavator Idler | Excavator Sprocket | Excavator Lower Roller | Excavator Undercarriage | Excavator Track Group | Excavator Bolts | Excavator Rock Bucket in Chennai | Excavator Skeleton Bucket in Chennai | Excavator Trapezoidal Bucket in Chennai | Excavator Soil Bucket in Chennai | Excavator Loader Bucket in Chennai | Excavator Single-Shank Ripper in Chennai | Excavator Triple-Shank Ripper in Chennai | Excavator Track Link Assembly in Chennai | Excavator Tooth Points in Chennai | Excavator JCB Teeth & Side Cutter in Chennai | Excavator Idler in Chennai | Excavator Sprocket in Chennai | Excavator Lower Roller in Chennai | Excavator Undercarriage in Chennai | Excavator Track Group in Chennai | Excavator Bolts in Chennai | Excavator Rock Bucket in India | Excavator Skeleton Bucket in India | Excavator Trapezoidal Bucket in India | Excavator Soil Bucket in India | Excavator Loader Bucket in India | Excavator Single-Shank Ripper in India | Excavator Triple-Shank Ripper in India | Excavator Track Link Assembly in India | Excavator Tooth Points in India | Excavator JCB Teeth & Side Cutter in India | Excavator Idler in India | Excavator Sprocket in India | Excavator Lower Roller in India | Excavator Undercarriage in India | Excavator Track Group in India | Excavator Bolts in India

TEAM. All Rights Reserved. Developed by Pixel Tech.