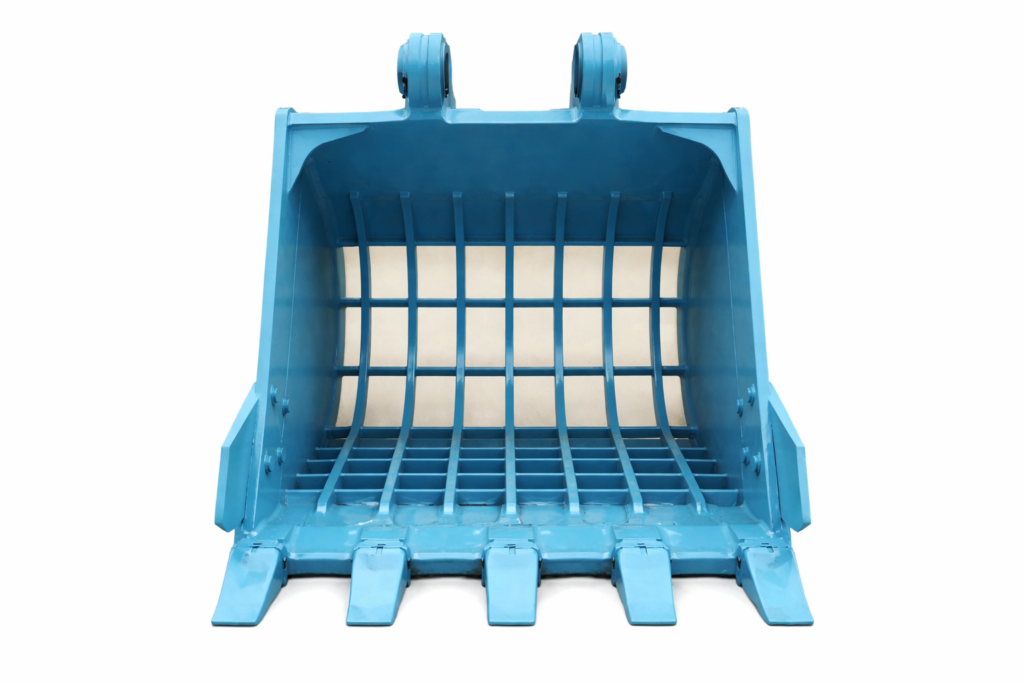

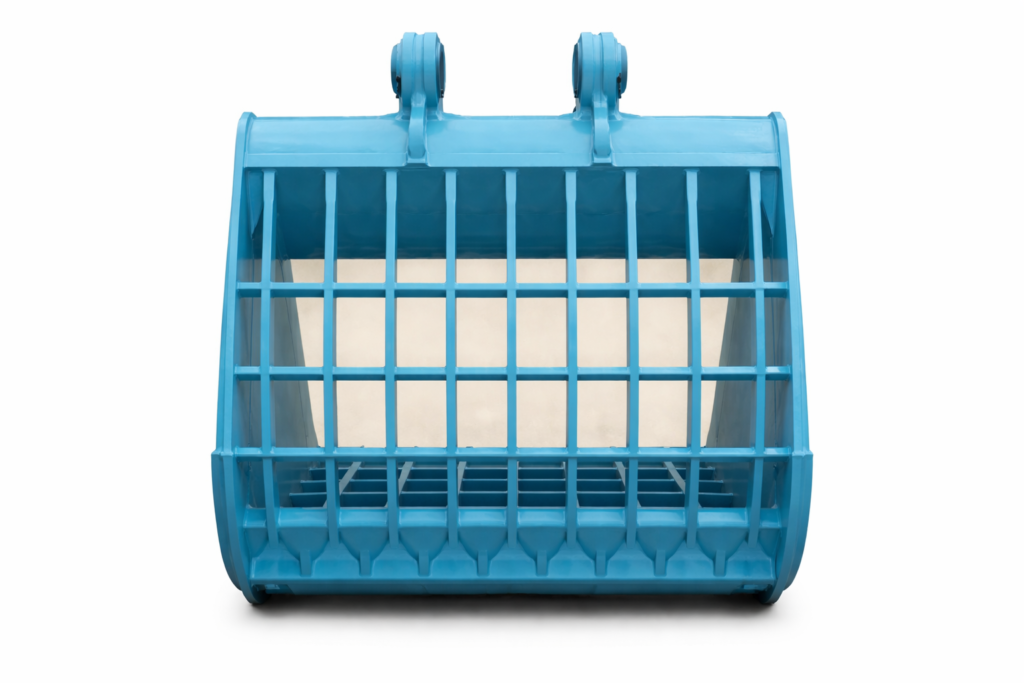

An Excavator Skeleton Bucket is a specialized attachment designed for sorting, sifting, and separating materials directly on-site. Unlike standard digging buckets, it features a grid- or rib-like structure with spaced bars that allow finer materials such as soil, sand, or smaller debris to fall through, while retaining larger rocks, stones, or construction waste.

Built with a durable and reinforced frame, the Excavator Skeleton Bucket combines the functions of digging and screening in a single attachment, eliminating the need for additional processing equipment. It is commonly used in applications like land clearing, recycling, demolition, landscaping, and quarry operations where material separation is essential.

Excavator Skeleton Bucket are available in different spacing sizes, widths, and capacities to suit various excavator models and project requirements. Their rugged design with wear-resistant materials ensures long service life, reduced downtime, and improved efficiency. By enabling operators to perform excavation and sorting simultaneously, they help increase productivity and reduce operating costs.

An Excavator Skeleton Bucket is a specially designed attachment used on excavators for separating finer materials from larger debris during excavation, site cleanup, and material handling tasks. Unlike a standard digging bucket, the Excavator Skeleton Bucket features a grid- or rib-like structure with evenly spaced gaps or slots along the bottom and sides. This unique design allows smaller particles such as soil, sand, or gravel to fall through the openings, while retaining larger materials like rocks, bricks, or construction debris.

Constructed from high-strength, wear-resistant steel, Excavator Skeleton Bucket are built to withstand heavy-duty applications while maintaining efficiency in sorting operations. They are particularly useful in industries such as construction, landscaping, agriculture, demolition, and quarrying—where separating materials on-site reduces the need for additional screening equipment.

Attachment and Compatibility: The Excavator Skeleton Bucket mounts directly to the excavator’s quick coupler or standard bucket linkage, enabling seamless switching from regular buckets. Operators can engage it just like a standard digging bucket without requiring special training.

Digging and Loading: During excavation, the bucket’s reinforced teeth penetrate hard ground or rocky surfaces. As the bucket scoops up the load, the ribbed framework immediately begins the natural sorting process.

Efficiency in Motion: With every movement of the bucket—digging, lifting, and shaking—unwanted fine materials sift out through the gaps between the ribs. This reduces the need for multiple passes or secondary screening equipment.

Natural Separation: The skeleton design incorporates strategically spaced ribs. When the bucket is filled, gravity pulls loose soil and smaller particles downward, allowing them to fall freely through the openings.

Controlled Shaking: Operators can enhance the separation process by gently shaking or tilting the bucket. This simple maneuver accelerates the screening action, ensuring only larger, usable materials remain inside.

Heavy-Duty Structure

Designed with reinforced high-strength steel, the bucket withstands harsh working environments such as rocky terrains, demolition sites, and quarry operations.

Side wear plates and thick cutting edges enhance impact resistance and reduce wear over prolonged usage.

Open Grid Design

The skeletal framework features evenly spaced ribs or tines that allow finer soil, sand, or small debris to fall through, while retaining larger rocks, stones, or waste material.

Grid spacing can be customized depending on the application (e.g., tighter spacing for finer separation, wider spacing for bulkier sorting).

A Skeleton Bucket is not just another attachment—it’s a specialized tool designed to maximize efficiency and productivity in excavation and material handling. By combining strength with selective screening ability, it provides several practical advantages on construction, demolition, and mining sites. Key benefits include:

The open-grid or ribbed design of a Excavator Skeleton Bucket allows fine materials like soil, sand, and small debris to fall through while retaining larger rocks, concrete chunks, or other solid waste. This built-in screening reduces the need for additional sorting equipment, saving time and operational costs.

When handling mixed materials, standard buckets often collect unwanted dirt or fines along with oversized material. Skeleton Buckets minimize contamination by naturally filtering out finer particles, ensuring cleaner loads for transportation, recycling, or backfilling.

Debris Sorting: Used to separate construction rubble, concrete chunks, and brick waste from soil or smaller aggregate for recycling and reuse.

Demolition Cleanup: Ideal for cleaning up after building or road demolition, where operators can quickly sift usable material from debris.

Site Preparation: Helps clear unwanted rocks and oversized particles while retaining useful soil for compaction or landscaping.

Soil Preparation: Separates stones, roots, and unwanted debris from topsoil, leaving behind fine soil suitable for planting and turf laying.

Land Clearing: Efficient for clearing fields, gardens, or large tracts of land where roots, branches, and rocks need to be removed.

Composting and Organic Handling: Used to sort organic waste, wood chips, and mulch materials without carrying excess dirt.

Excavator Classes: Excavator Skeleton Bucket are available for mini, midi, and full-size excavators, typically ranging from 1-ton compact machines to 50+ ton heavy-duty excavators.

Coupler Systems: They are engineered to fit standard pin-on mounts as well as quick coupler systems (manual or hydraulic), allowing operators to switch attachments rapidly without downtime.

OEM & Aftermarket Fit: Leading manufacturers produce Excavator Skeleton Bucket tailored for specific brands and models, ensuring seamless fitment with OEM specifications. Universal aftermarket options are also available for broader compatibility.

Width Options: Excavator Skeleton Bucket come in multiple widths, generally ranging from 300 mm (12 inches) for compact units to over 2,000 mm (80 inches) for large-scale excavation projects.

Capacity Range: Bucket volume varies with width and depth, typically from 0.1 m³ for mini excavators up to 2.5+ m³ for large excavators, allowing operators to balance load size with machine capability.

Weight Ratings: To prevent overloading, Excavator Skeleton Bucket are manufactured with weight classes that match the operating capacity of the excavator, ensuring safe and stable operation.

Daily Inspection: Operators should conduct a quick visual check before and after use to identify cracks, bent tines, or unusual wear patterns on the cutting edge, ribs, and bucket shell.

Lubrication: All hinge and pin joints must be regularly greased to minimize friction and prevent premature wear in pivot areas.

Cleaning After Use: Since Excavator Skeleton Bucket are exposed to sticky or abrasive materials, it is important to remove trapped soil, rock fragments, or debris lodged between ribs to avoid added stress and uneven wear.

Welding Repairs: Minor cracks or surface wear can be managed early with weld build-ups using wear-resistant electrodes, helping to prevent costly structural failures.

Excavator Skeleton Bucket are designed with modular, replaceable components to keep the bucket operational even under heavy-duty usage:

Cutting Edge (Bolt-On or Weld-On): The primary wear component, constantly in contact with abrasive material. Bolt-on cutting edges are replaceable and allow quick restoration of cutting efficiency.

Side Cutters / Side Wear Plates: Protect the side walls of the bucket from grinding wear when digging

Design: Standard digging buckets feature solid sidewalls and a closed structure for maximum material retention, while Excavator Skeleton Bucket are constructed with reinforced ribs and gaps that allow finer material to pass through.

Function: A digging bucket is ideal for general excavation, soil handling, and trenching, whereas a Excavator Skeleton Bucket is best for separating oversized rocks, debris, or waste from finer soil or sand.

Design: Rock buckets are built with thicker steel, reinforced cutting edges, and wear-resistant plates for breaking and handling abrasive rock. Excavator Skeleton Bucket, while strong, are lighter and designed with slots for material separation.

Function: Rock buckets excel at penetrating hard rock, quarry work, and high-impact digging. Excavator Skeleton Bucket, on the other hand, are meant for sorting and sifting through mixed material rather than heavy breaking.

Weight Compatibility: The Excavator Skeleton Bucket must be sized appropriately for your excavator’s lifting capacity and hydraulic power. An oversized bucket can overload the machine, while an undersized one reduces efficiency.

Mounting Fit: Ensure the bucket is compatible with your excavator’s quick coupler or pin dimensions to avoid modifications or downtime.

Rock and Heavy Debris: Opt for a heavy-duty skeleton bucket with reinforced wear plates, thicker side walls, and hardened steel tines.

Topsoil, Sand, and Light Aggregates: A lighter skeleton bucket with wider spacing between ribs may be sufficient.

Attachment Inspection: Examine the Excavator Skeleton Bucket for visible cracks, worn edges, loose pins, or damaged welds before use. Any structural defect can compromise safety.

Pin & Coupler Check: Ensure that all pins, bushings, and quick coupler systems are properly locked in place to avoid accidental detachment.

Load Capacity Compliance: Never exceed the rated load capacity of the excavator or the Excavator Skeleton Bucket. Overloading may lead to equipment failure or tipping hazards.

Balanced Loading: Avoid filling the bucket unevenly, as imbalanced loads can strain the attachment and affect excavator stability.

Caterpillar is one of the world’s most trusted heavy equipment manufacturers, and its range of Excavator Skeleton Bucket is widely known for rugged design and excellent material separation.

Notable Models:

CAT Skeleton Buckets – General Duty Series: Designed for light to medium-duty applications like landscaping, sorting, and backfilling.

CAT Heavy-Duty Skeleton Buckets: Reinforced with abrasion-resistant steel for quarry and demolition work.

Key Features: CAT buckets often include wide spacing between ribs, cutting edges with optional teeth, and optimized load capacity for maximum productivity.

JCB offers Excavator Skeleton Buckettailored for its own excavators but also compatible with other makes. They are valued for their versatility in separating finer materials from larger debris.

Notable Models:

JCB Excavator Skeleton Bucket (sizes ranging from mini to large excavator classes).

Key Features: Built with durable high-tensile steel ribs, reinforced side walls, and bolt-on cutting edges for long life and easy maintenance.

Q1. What is an Excavator Skeleton Bucket used for?

An excavator skeleton bucket is primarily used for separating rocks, debris, and oversized materials from soil or finer aggregates. Its slotted or grid-like design allows smaller particles to fall through while retaining larger materials, making it ideal for sorting, land clearing, demolition cleanup, and quarry operations.

Q2. How is a skeleton bucket different from a standard bucket?

Unlike a standard bucket, which is designed for bulk digging and material handling, a skeleton bucket features spaced ribs or bars. This structure enables efficient screening and sorting, reducing the need for secondary processing and saving time on-site.

Q3. What materials can I handle with a skeleton bucket?

Skeleton buckets are suitable for handling:

Rocks, stones, and gravel

Demolition debris

Topsoil and organic material

Quarry waste

Recyclable construction material

Q4. Can I use a skeleton bucket for digging?

Yes, skeleton buckets can perform light to moderate digging, especially in rocky or loose soil conditions. However, for heavy-duty excavation or trenching in compacted ground, a standard or rock bucket is more efficient.

Q5. What size excavator can use a skeleton bucket?

Skeleton buckets are manufactured in various sizes to fit different excavators, ranging from mini excavators (1–8 tons) to large excavators (40+ tons). Always ensure compatibility by checking the bucket’s weight, width, and pin dimensions with your excavator.

Q6. Are skeleton buckets customizable?

Yes, many manufacturers offer customization options such as bar spacing, bucket width, and reinforced edges to suit specific applications like quarrying, demolition, or landscaping.

Q7. Does using a skeleton bucket reduce fuel costs?

Yes. Since it screens and separates material on-site, fewer loads need to be transported or processed, leading to lower fuel consumption, reduced machine wear, and overall cost savings.

Q8. How do I maintain a skeleton bucket?

Inspect the ribs and side plates regularly for cracks or excessive wear.

Grease the pins and bushings as per your excavator’s maintenance schedule.

Avoid overloading to prevent bending of the bars.

Store in a dry area to minimize corrosion when not in use.

Q9. Can skeleton buckets be used in demolition projects?

Absolutely. They are widely used in demolition to sort concrete, rebar, and rubble, making recycling easier and more cost-effective.

Q10. Is operator training required for using a skeleton bucket?

Basic excavator operating skills are sufficient. However, training operators on how to properly use the screening action—such as shaking or raking motions—will maximize efficiency and extend the bucket’s life.

TEAM. All Rights Reserved. Developed by Pixel Tech.