When it comes to construction, mining, or material-handling operations, one of the most essential attachments for heavy equipment is the Excavator Loader Bucket. Acting as the primary interface between the machine and the material, these buckets are designed to scoop, carry, and dump materials efficiently. From digging foundations to handling aggregates, an Excavator Loader Bucket plays a critical role in boosting productivity and versatility on job sites.

In this article, we’ll explore the types, functions, and applications of excavator loader buckets — helping you understand how to select the right one for your project.

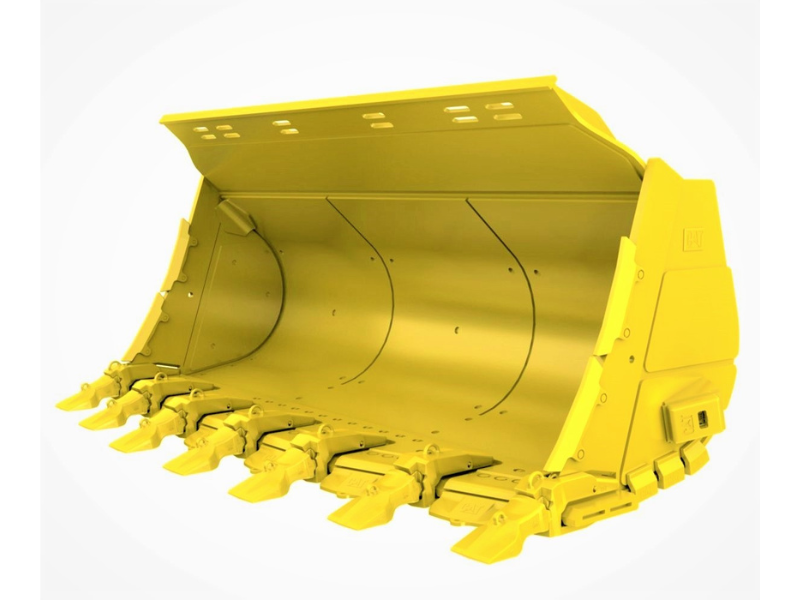

An Excavator Loader Bucket is a steel attachment mounted at the end of an excavator or backhoe loader’s arm. It’s designed to handle various materials such as soil, gravel, sand, rocks, and debris. Depending on the bucket’s shape, size, and tooth configuration, it can perform a range of tasks — from digging and grading to loading and trenching.

Modern excavator loader buckets are built with high-strength materials to withstand heavy-duty conditions. Many are equipped with reinforced cutting edges and wear plates to enhance durability and extend service life.

Different projects require different bucket types. Here are the most common types of Excavator Loader Buckets and their specific uses:

Also known as the standard bucket, this is the most commonly used type. It’s ideal for light to medium-duty digging and loading tasks like handling soil, sand, and gravel. It offers a balance between capacity and strength, making it suitable for everyday construction work.

Designed for tough applications, the heavy-duty excavator loader bucket features thicker side plates, stronger welds, and reinforced edges. It’s perfect for digging in compacted soil, clay, or rocky conditions.

A rock bucket is specifically engineered for mining and quarrying operations. It comes with strong teeth, a V-shaped cutting edge, and wear-resistant materials that allow it to break through hard rock and dense materials with ease.

This wide and shallow bucket is primarily used for grading, leveling, and cleaning ditches. It doesn’t have teeth and is designed for smooth finishing work in landscaping and road maintenance.

As the name suggests, this bucket is used for digging narrow trenches — typically for laying cables, pipelines, or drainage systems. It’s narrower and deeper, enabling precision digging in confined spaces.

A skeleton bucket has gaps between its ribs, allowing smaller particles like sand or soil to fall through while retaining larger materials such as rocks. It’s often used in sorting and screening applications.

This versatile bucket can tilt up to 45 degrees on either side, making it ideal for sloping, shaping, and grading uneven terrain. It’s a favorite for landscaping and finishing jobs.

The Excavator Loader Bucket is more than just a digging tool — it’s a multifunctional attachment that enhances operational efficiency. Its main functions include:

Digging: Breaking and removing soil, clay, or other materials.

Loading: Lifting and transferring materials into trucks or onto conveyors.

Grading: Leveling surfaces and preparing areas for construction or landscaping.

Trenching: Creating narrow, deep cuts for pipes or utilities.

Material Handling: Moving bulk materials, waste, or debris efficiently.

Some buckets also come with quick couplers, allowing operators to switch attachments easily and maximize machine flexibility.

Because of their adaptability, Excavator Loader Buckets are used across a wide range of industries:

Construction: Excavation, foundation work, road building, and debris removal.

Mining and Quarrying: Handling minerals, rocks, and aggregates.

Agriculture: Loading soil, fertilizers, and harvested materials.

Landscaping: Leveling land, trenching for irrigation, and grading surfaces.

Waste Management: Clearing debris and handling bulk waste.

Their design versatility allows operators to match the bucket type to the specific needs of the job — optimizing performance and minimizing wear.

When selecting an Excavator Loader Bucket, consider factors like:

Material Type: Softer materials require lightweight buckets, while hard or abrasive materials need reinforced options.

Bucket Capacity: Must match the excavator’s hydraulic power and stability.

Work Conditions: Harsh environments may need special coatings or wear plates.

Application Needs: Choose a bucket designed specifically for the task — digging, grading, or loading.

Investing in the right bucket can significantly improve productivity, reduce fuel consumption, and extend machine lifespan.

The Excavator Loader Bucket is the powerhouse behind efficient earthmoving and material-handling operations. With the right type and configuration, it can transform any excavator or loader into a versatile, high-performance machine. Understanding the various types, functions, and applications ensures you choose the best fit for your project — maximizing both output and cost efficiency.

Whether you’re in construction, mining, or landscaping, the right Excavator Loader Bucket will always be at the heart of productivity.

TEAM. All Rights Reserved. Developed by Pixel Tech.