When it comes to heavy machinery, Excavator Undercarriage components are the backbone of performance, stability, and durability. The undercarriage supports the entire weight of the excavator, enabling it to move, work on different terrains, and handle heavy loads efficiently. Whether you’re operating in construction, mining, forestry, or roadwork, understanding the undercarriage and its components is critical for maintenance, cost savings, and extending machine life.

In this complete guide, we’ll break down the main Excavator Undercarriage components, their functions, and the best practices for upkeep.

The undercarriage is often referred to as the foundation of the excavator. It accounts for nearly 50% of the machine’s total maintenance costs due to the constant wear and tear it undergoes on harsh terrains. Proper understanding and care of the undercarriage can:

Increase machine lifespan

Improve stability and traction

Reduce downtime and repair expenses

Enhance productivity across various applications

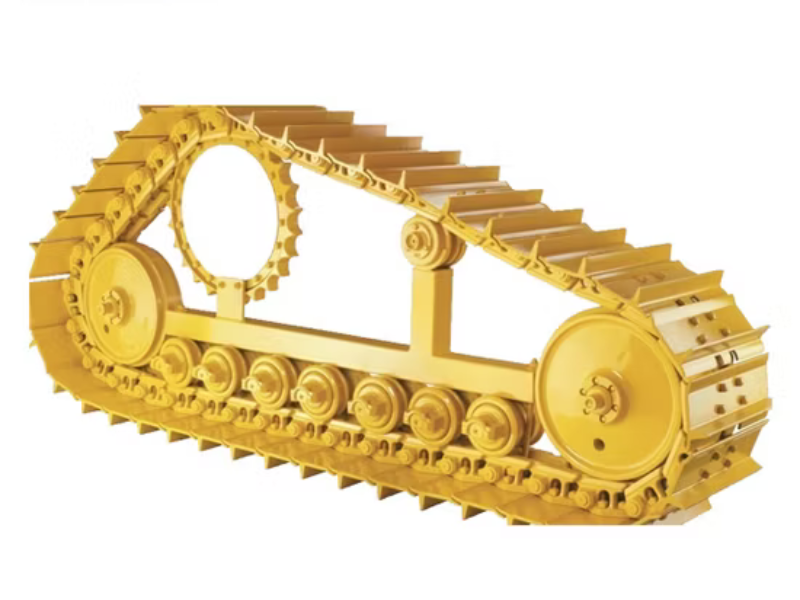

Track chains form the framework that keeps the machine mobile. They connect to the track shoes and run along the sprockets and idlers.

Function: Provides movement and supports the excavator’s weight.

Maintenance Tip: Inspect for stretched links, wear, and cracks. Keep them lubricated or sealed depending on the type.

Track shoes, also known as grousers, are the wide steel or rubber plates that make direct contact with the ground.

Function: Provides traction and distributes machine weight evenly across surfaces.

Maintenance Tip: Replace worn-out track shoes promptly to avoid uneven stress on other components. Choose shoes designed for your terrain (e.g., wider for soft soil, narrower for rocky surfaces).

The sprockets are toothed wheels that engage with the track links to drive the excavator forward or backward.

Function: Transfers power from the engine to the tracks.

Maintenance Tip: Check for worn or broken teeth. Replacing sprockets in pairs with chains is ideal to prevent premature wear.

Idlers are mounted at the front of the undercarriage and help guide the track chains while maintaining tension.

Function: Reduces track chain slack and absorbs shock during movement.

Maintenance Tip: Ensure idlers are properly aligned and tensioned to prevent uneven wear on track chains.

Bottom Rollers: Support the weight of the machine and keep the track chain aligned.

Top Rollers (Carrier Rollers): Guide the chain back to the sprockets smoothly.

Function: Both distribute weight and help the excavator move efficiently on rough terrains.

Maintenance Tip: Regularly check for oil leaks, unusual noises, or flat spots.

Track adjusters control the track tension by moving the idler forward or backward.

Function: Keeps the track chain at the correct tension for optimal performance.

Maintenance Tip: Avoid over-tightening as it accelerates wear on chains and rollers.

The track frame is the structural base that holds all undercarriage components together.

Function: Provides durability, strength, and proper alignment of parts.

Maintenance Tip: Inspect for cracks, bends, or loose bolts to ensure stability.

Daily Inspections – Walk around your machine to check for loose bolts, track tension, oil leaks, or damaged shoes.

Proper Track Tension – Keep tracks at manufacturer-recommended tension; too tight or too loose accelerates wear.

Regular Cleaning – Remove mud, rocks, and debris stuck in the undercarriage after each shift. This prevents corrosion and misalignment.

Rotate Track Chains – Periodically rotate the chains to promote even wear and extend service life.

Operate Correctly – Avoid unnecessary spinning, sharp turns on abrasive surfaces, or driving at high speeds on hard ground.

Since the undercarriage is one of the costliest parts to maintain, proactive care is essential. Investing in quality components, conducting regular inspections, and following proper operating techniques can help extend its service life significantly. Additionally, partnering with a trusted supplier for Excavator Undercarriage parts ensures that replacements meet OEM standards and deliver long-term reliability.

The Excavator Undercarriage plays a vital role in ensuring smooth operations, safety, and cost efficiency. By understanding its components and practicing consistent maintenance, operators can minimize downtime, reduce repair expenses, and maximize productivity. Whether you’re in construction, mining, or infrastructure projects, a well-maintained undercarriage is the foundation of a successful operation.

TEAM. All Rights Reserved. Developed by Pixel Tech.