The Excavator Loader Bucket is one of the most essential attachments in construction, mining, and earthmoving operations. Designed for digging, lifting, and moving materials such as soil, gravel, and debris, it enhances the versatility and productivity of an excavator. However, operating this equipment safely and efficiently requires knowledge, skill, and adherence to industry best practices. Improper use can lead to equipment damage, costly downtime, and even severe injuries. This guide outlines the best practices to ensure optimal performance and safety when using an excavator loader bucket.

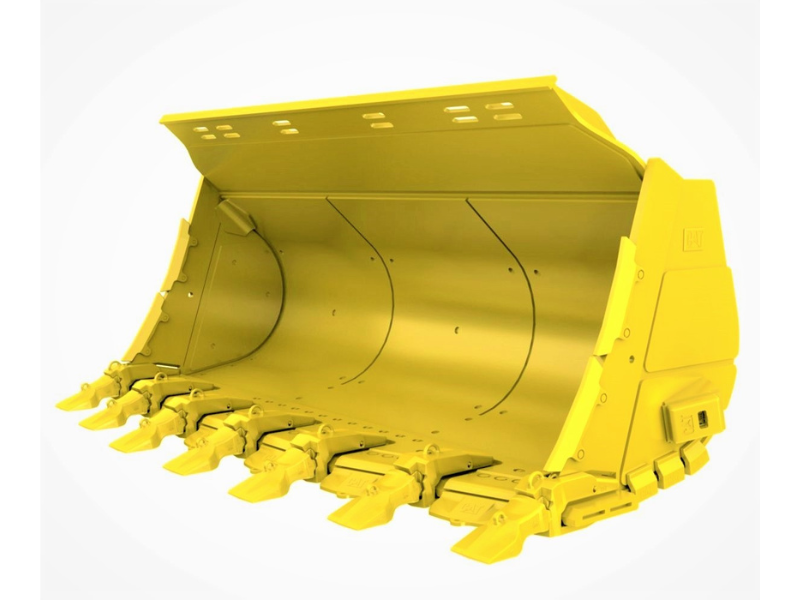

Before operating an Excavator Loader Bucket, it’s crucial to understand its functions and limitations. The bucket’s size, shape, and capacity directly influence its performance. Larger buckets move more material per scoop but may reduce maneuverability, while smaller buckets offer precision but require more cycles. Familiarizing yourself with the bucket’s specifications, weight limits, and compatible materials is essential for efficient operation.

A thorough inspection before starting any task is a critical step in safe operation. Check the bucket for signs of wear, cracks, or dents that could compromise performance. Inspect the pins, hinges, and hydraulic connections to ensure they are secure and functioning correctly. Hydraulic fluid levels should be adequate, and any leaks should be addressed immediately. Regular inspections not only prevent accidents but also extend the lifespan of the equipment.

Ensuring that the Excavator Loader Bucket is correctly mounted to the excavator is vital. Improper attachment can lead to bucket detachment or uneven load distribution, increasing the risk of accidents. Follow the manufacturer’s instructions for attachment, and double-check locking mechanisms. Using quick couplers, where available, can enhance efficiency but must be operated correctly to avoid accidental releases.

Safety should always be the top priority when using an excavator loader bucket. Operators should:

Wear appropriate PPE: Helmets, gloves, safety boots, and high-visibility clothing are essential.

Maintain clear communication: Use signals or radios to coordinate with ground personnel.

Be aware of surroundings: Ensure the area is clear of obstacles, power lines, and personnel.

Avoid overloading: Exceeding the bucket’s capacity can strain the hydraulic system and cause tip-overs.

Use proper digging techniques: Position the bucket for maximum efficiency, digging from the sides or top-down as needed, and avoid dragging the bucket across the ground unnecessarily.

Efficiency in operating an Excavator Loader Bucket comes from smooth, controlled movements. Minimize unnecessary swings and rotations to reduce fuel consumption and wear. Use the bucket to scoop materials efficiently by approaching the pile at an angle that maximizes fill and minimizes spillage. When dumping materials, ensure the target area can support the load without causing instability.

Regular maintenance of the bucket and the excavator ensures long-term efficiency. Clean the bucket after use to prevent rust and material buildup. Check for worn teeth, and replace them as needed to maintain digging efficiency. Hydraulic components should be serviced according to the manufacturer’s schedule. Keeping the equipment in peak condition prevents unexpected breakdowns and enhances operational safety.

No matter how advanced the equipment is, the operator’s skill determines productivity and safety. Investing in proper training for operators ensures they understand load limits, proper digging techniques, and emergency procedures. Skilled operators can handle the Excavator Loader Bucket with precision, reducing the risk of accidents and maximizing efficiency.

Operating an Excavator Loader Bucket safely and efficiently is a blend of proper knowledge, technique, and maintenance. By understanding the equipment, conducting thorough inspections, following safe operating practices, handling materials efficiently, and ensuring regular maintenance, operators can achieve optimal performance while minimizing risks. Prioritizing safety and efficiency not only protects workers but also enhances productivity and prolongs the life of the excavator.

In the fast-paced world of construction and earthmoving, mastering these best practices is essential for any professional seeking to get the most out of their excavator loader bucket.

TEAM. All Rights Reserved. Developed by Pixel Tech.