When it comes to excavation and earthmoving, choosing the right bucket for your excavator can significantly impact efficiency, safety, and project outcomes. Among the most commonly used types are standard excavator buckets and the increasingly popular trapezoidal buckets. Understanding the differences between these two can help construction professionals make informed decisions for different soil types, trenching requirements, and project scopes.

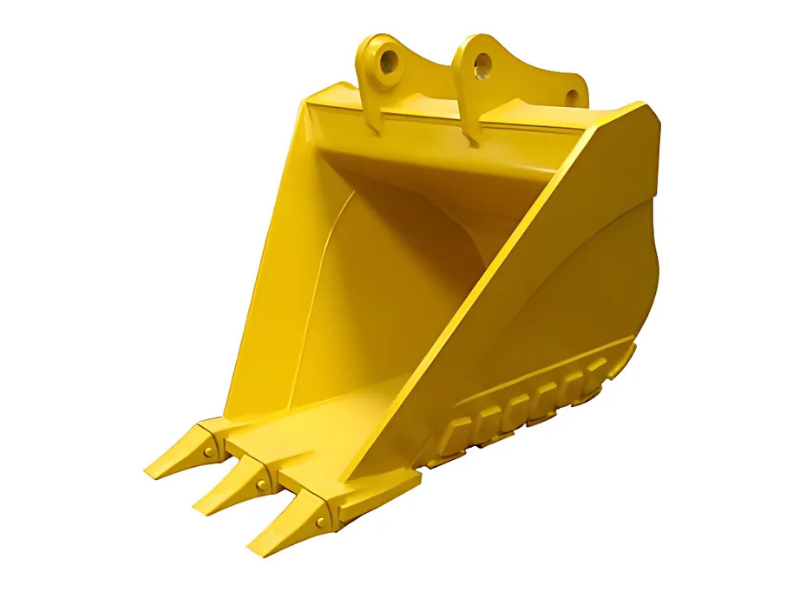

Standard excavator buckets are the most widely used attachment across construction sites. They come in various sizes and capacities to match the excavator’s tonnage, making them highly versatile. These buckets usually have a rectangular or slightly tapered shape with teeth at the edge to penetrate hard soils, clay, or compacted materials.

Key features of standard excavator buckets:

Versatility: Suitable for digging, lifting, and loading a wide range of soil types.

Durability: Made from high-strength steel to withstand abrasive conditions.

Availability: Easily available and compatible with most excavator models.

Efficiency: Designed for general-purpose excavation, making them ideal for bulk earthmoving.

However, standard buckets have limitations when it comes to precision digging, trench shaping, and working in unstable or cohesive soil. Their wide, straight edges are not always suitable for creating trenches with angled sides or for minimizing soil disturbance in sensitive projects.

The Excavator Trapezoidal Bucket is designed to address the limitations of standard buckets. As the name suggests, it has a trapezoidal shape, which makes it narrower at the bottom and wider at the top. This unique design allows for precise trench digging, especially for pipelines, cables, and drainage systems.

Advantages of Excavator Trapezoidal Buckets:

Precision Digging: The tapered shape allows for accurate trench profiles without excessive backfill or soil removal.

Reduced Soil Disturbance: Ideal for urban areas or sensitive sites where minimal soil displacement is crucial.

Improved Safety: Less soil spillage reduces the risk of trench collapses and improves stability.

Optimized Material Handling: The bucket shape ensures better material flow, making loading and unloading faster and more efficient.

These buckets are particularly useful in projects where trenching requires specific dimensions and clean edges. Unlike standard buckets, trapezoidal buckets minimize overcutting and save time during backfilling, leveling, and compaction.

Selecting the right bucket depends on the nature of the project and the type of soil being excavated:

Project Type:

Standard buckets are perfect for general construction, roadwork, or large-scale excavation.

Trapezoidal buckets excel in pipeline installation, drainage trenches, and other precision-based excavation.

Soil Condition:

Standard buckets handle heavy, compact, or rocky soils effectively.

Trapezoidal buckets are ideal for cohesive soils or when precision is required to avoid unnecessary soil disruption.

Excavation Accuracy:

Standard buckets provide speed but less precision.

Trapezoidal buckets offer precise trench dimensions, reducing the need for additional grading.

While standard excavator buckets remain indispensable for general-purpose excavation, the Excavator Trapezoidal Bucket has carved its niche in modern construction projects that demand precision, safety, and efficiency. By understanding the differences, construction managers and operators can optimize their equipment usage, reduce project time, and enhance overall productivity.

Whether you are planning large-scale earthmoving or delicate trench work, choosing the right bucket can make all the difference. For tasks that require clean trench profiles, minimal soil displacement, and improved operational efficiency, the Excavator Trapezoidal Bucket is clearly the smarter choice.

TEAM. All Rights Reserved. Developed by Pixel Tech.